What Are the Common Causes of Oil Immersed Transformer Failures?

There are several reasons why oil immersed transformers can fail. One common cause is overheating. When transformers get too hot, it can damage the insulation inside them. This insulation is very important because it helps keep the electrical parts from touching each other. If the insulation breaks down, it can lead to short circuits. Short circuits can cause transformers to fail completely. Another cause is moisture. Water can get into the oil, and that is not good. Water in oil can lead to rust and other damage, which can make the transformer less effective. Dirt and dust can also get into the transformer and cause problems. If dirt builds up, it can block cooling systems, leading to overheating. Finally, mechanical issues, like loose connections or worn-out parts, can contribute to failures. If connections are not tight, it can create sparks and lead to fires. Regular maintenance is key to catching these problems before they lead to a failure. For example, checking oil levels and inspecting for leaks can help identify issues early. Yawei recommends doing these checks often to keep transformers in good shape.

How to Diagnose Oil Immersed Transformer Issues Effectively

Diagnosing problems in oil immersed transformers can be tricky, but it is very important. First, it is vital to look for visible signs of trouble. This includes checking for leaks or unusual sounds. If a transformer is making a humming noise that is louder than normal, that could be a sign of a problem. Another step is to test the oil itself. Oil can show signs of wear and tear, like color changes or particles. If the oil is dirty or has a strange smell, it may be time to change it. Using special tools, technicians can measure the levels of gas in the oil. If gas levels are high, that can indicate that the transformer is having trouble. Keeping a record of these tests can help track changes over time. Regular check-ups can catch issues early. Yawei believes that communication is also key. If workers notice something strange, they should report it right away. This helps ensure that everyone is aware of the situation and can work together to fix it. Overall, diagnosing transformer issues involves a mix of careful observation, regular testing, and teamwork to keep everything running smoothly.

How to Enhance the Lifespan of Oil Immersed Transformers

Taking good care of oil immersed transformers is very important for making them last longer. One of the best ways to enhance their lifespan is through regular maintenance. This means checking the transformers often to make sure everything is working as it should. You should look for any signs of wear and tear, like leaks or rust. If you find something that doesn’t look right, it’s better to fix it quickly before it becomes a bigger problem. Another important tip is to keep the area around the transformer clean and dry. Dirt and moisture can cause damage over time, so keeping the area tidy can really help. It is also essential to keep the oil at the right level. The oil inside the transformer helps cool it down and keeps it running smoothly. If the oil level gets too low, the transformer can overheat and fail. Therefore, checking the oil level regularly is a must.

Using high-quality parts when making or repairing transformers is also a smart move. Good parts can prevent many problems and make the transformer last longer. At Yawei, we focus on providing top-quality components that can withstand the test of time. Lastly, training the staff who work with transformers is very important. They should know how to operate and maintain the transformers properly. When people understand how to take care of these machines, it can help them work better and last longer. By following these simple steps—regular maintenance, keeping the area clean, checking oil levels, using quality parts, and training staff—everyone can help enhance the lifespan of oil immersed transformers.

How to Recognize Signs of Oil Immersed Transformer Malfunction

Recognizing the signs of a malfunctioning oil immersed transformer is crucial for preventing bigger problems. One of the first signs to look out for is unusual noises. If the transformer starts making humming, buzzing, or any strange sounds, it could indicate that something’s wrong. It’s important to pay attention to these noises, as they may mean there is a problem that needs fixing. Another sign to watch for is changes in temperature. If the transformer is too hot to touch or if the temperature rises above normal levels, it could be overheating. Overheating can cause serious damage, so it’s vital to address this issue promptly.

You should also check for leaks. If you notice oil pooling around the transformer, that’s a clear sign that something is not right. Oil leaks can lead to a lack of insulation, making the transformer less effective. Additionally, you should keep an eye on the performance of the transformer. If it starts to show a drop in efficiency or if it struggles to handle loads, it’s a warning that something could be wrong inside. Lastly, monitoring the oil quality is very important. If the oil looks dirty or has a strange smell, it may be time to replace it. At Yawei, we recommend regularly testing the oil to ensure it is clean and effective. By being aware of these signs—unusual noises, changes in temperature, leaks, drops oil filled pad mounted transformer in performance, and poor oil quality—you can catch problems early and keep the transformer running smoothly.

Where to Source Quality Components for Oil Immersed Transformers

When it comes to oil immersed transformers, using quality components is extremely important. Finding the right parts can make a big difference in how well the transformer works and how long it lasts. One of the best places to source quality components is from trusted manufacturers. Look for companies that specialize in making parts for transformers, like Yawei. We focus on high-quality materials and designs that meet industry standards. This ensures that the components will work properly and last a long time.

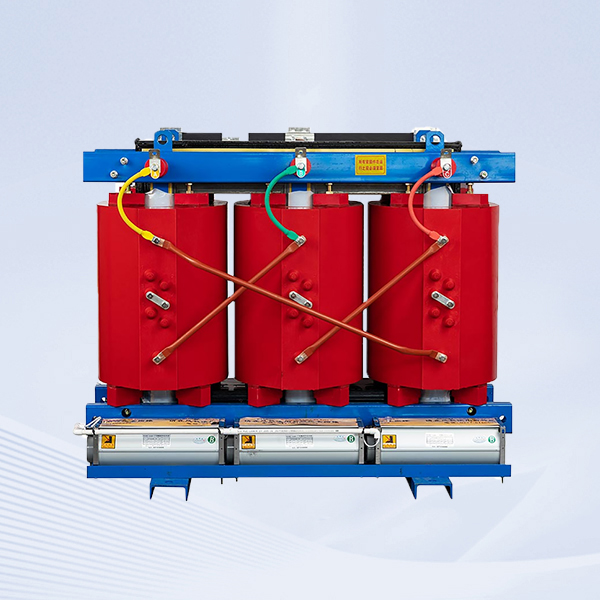

Another good approach is to check for recommendations from cast coil dry type transformer professionals in the field. Electricians and engineers who work with transformers often have a good idea of where to find reliable parts. They can share their experiences and point you in the right direction. Online reviews are also a helpful resource. Websites that sell transformer parts usually have reviews from customers. Reading these reviews can give you an idea of the quality of the components and whether other people have had good experiences with them.

It’s also important to consider the warranty and support offered by the supplier. A good warranty can provide peace of mind, knowing that if something goes wrong, you can get help. Finally, attending trade shows or industry conferences can be a great way to connect with suppliers and learn about the latest technologies and parts available. By sourcing quality components from oil immersed transformer trusted manufacturers, seeking professional recommendations, checking reviews, considering warranties, and attending industry events, you can ensure that your oil immersed transformers are built to last.